Mastering Cable Installation with Wire Pulling Socks: Technical Details for Safe and Effective Cable Pulling.

Wire pulling socks are made of a flexible wire mesh material that can grip the…

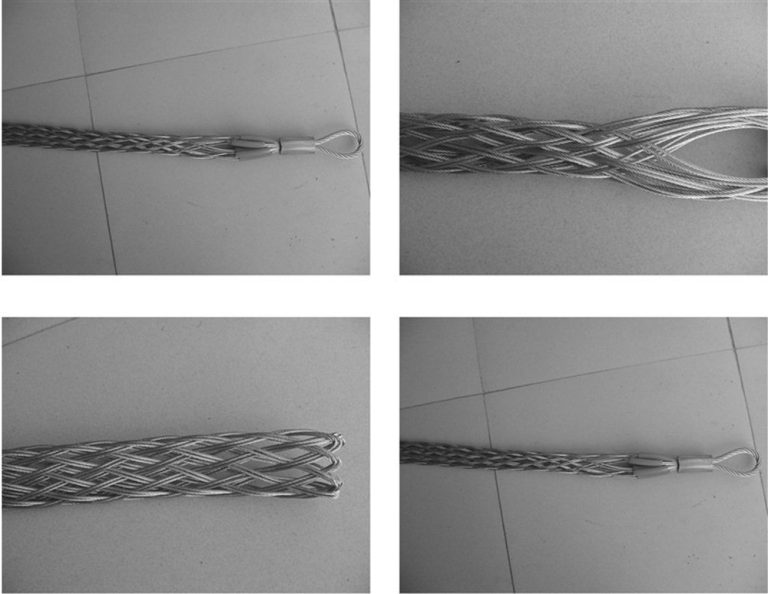

Wire pulling socks are made of a flexible wire mesh material that can grip the cable tightly without damaging it. The wire mesh material is typically made of galvanized steel or stainless steel, which is resistant to corrosion and can withstand the weight and tension of heavy cables.

Wire pulling socks come in a range of sizes to fit different cable diameters, and different styles to suit different installation scenarios. The most common types of wire pulling socks include standard duty, heavy duty, rotating eye, and offset eye. Each style has its own unique features and benefits, making them suitable for different types of cable pulling applications.

Standard duty wire pulling socks are suitable for most cable pulling applications and are designed to provide a secure grip on the cable during the installation process. Heavy duty wire pulling socks are designed for larger cables and heavier pulling applications. They are made of thicker wire mesh material and have a higher weight capacity than standard duty socks.

Rotating eye wire pulling socks have a swivel eye that rotates freely, allowing the cable to be pulled in any direction without twisting or damaging the cable. Offset eye wire pulling socks have a curved eye that is offset from the center of the sock, making it easier to attach to the cable and providing a more secure grip.

Wire pulling socks are typically installed by sliding the sock onto the cable and positioning it in the desired location. The sock should be positioned so that it will provide a secure grip on the cable during the pulling process. Once the sock is attached to the cable, the cable pulling process can begin.

Throughout the cable pulling process, it’s important to monitor the sock and cable for any signs of damage or slipping. If the sock begins to slip or the cable is showing signs of damage, the pulling process should be stopped immediately to avoid further damage or accidents.

In summary, wire pulling socks are a versatile and reliable tool for cable installation in many industries. They provide a strong and secure grip on the cable, come in a range of sizes and styles to suit different installation scenarios, and are made of durable materials that can withstand harsh environmental conditions. By selecting the appropriate size and style, attaching the sock to the cable correctly, and monitoring the cable pulling process, you can ensure a safe and successful installation process.

cable stocking grip, pulling socks for wire, greenlee wire grip, split mesh cable grip, cable puller grip sock, klein wire mesh grips, greenlee pulling socks, conductor socks, klein wire mesh grip, slingco pulling grips.