Smooth Operations: Understanding the Function and Importance of Stringing Rollers in Power Line Construction

In the realm of power line construction, various specialized tools and equipment are essential for…

In the realm of power line construction, various specialized tools and equipment are essential for ensuring efficient and safe operations. One such indispensable tool is the stringing roller, a device that plays a critical role in the installation and maintenance of power lines. In this article, we will explore the function of stringing rollers and their importance in power line construction projects.

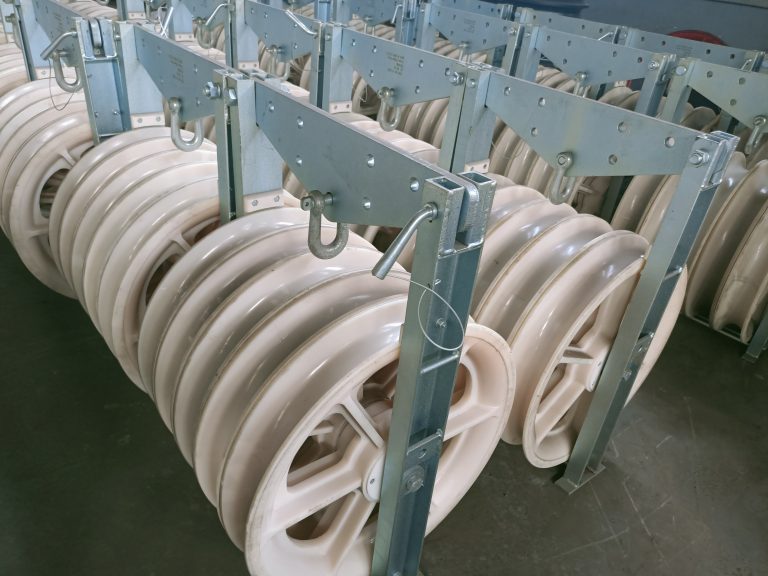

Stringing rollers, also known as conductor rollers or cable rollers, are devices designed to support and guide conductors or cables during the installation process. They are strategically placed along the route of the power line to facilitate the smooth passage of the conductor, minimizing friction and preventing damage to the conductor’s surface. Stringing rollers also help maintain proper tension on the conductor throughout the installation process, ensuring an efficient and safe operation.

There are various types of stringing rollers, each designed for specific applications and environmental conditions. Some of the most common types include:

- Straight Line Rollers: These rollers are used in areas where the power line runs in a straight line, and no significant changes in direction are required. They are typically mounted on cross-arms or support structures, providing a simple and effective means of guiding the conductor.

- Corner Rollers: Corner rollers are designed to facilitate changes in direction along the power line route. They feature a curved or angled design that enables the conductor to navigate turns and bends with minimal friction and stress.

- Suspension Rollers: These rollers are specifically designed for use in suspension bridges, towers, or other elevated structures. They are equipped with a swivel mechanism that allows the conductor to move freely in multiple directions, making them ideal for handling the dynamic loads and movements associated with suspension structures.

- Ground Rollers: Ground rollers are used to guide and support conductors as they are pulled across the ground during installation. They are typically placed at regular intervals along the power line route to minimize friction and prevent damage to the conductor.

The use of stringing rollers in power line construction projects offers several key benefits:

- Improved Efficiency: Stringing rollers streamline the conductor installation process by minimizing friction and facilitating smooth movement. This translates to faster installation times and reduced labor costs.

- Enhanced Safety: By maintaining proper tension on the conductor and preventing damage, stringing rollers help reduce the risk of accidents and injuries associated with conductor installation and maintenance.

- Increased Lifespan of Conductors: Stringing rollers protect conductors from abrasion and damage during installation, ultimately extending their lifespan and reducing the need for costly repairs or replacements.

- Adaptability: With a variety of stringing roller types available, power line construction professionals can select the most appropriate rollers for their specific project requirements, ensuring optimal performance in various environments and conditions.

In conclusion, stringing rollers are an essential component of power line construction projects, playing a critical role in the safe and efficient installation of conductors. By understanding the function and importance of stringing rollers, power line construction professionals can optimize their use and achieve the best possible outcomes for their projects.