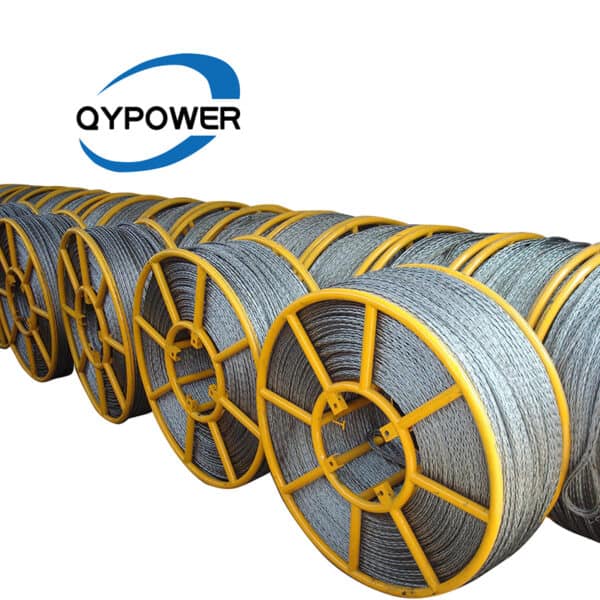

Pulling Cable Pilot Wire Rope

Scope of application: This Pilot Wire Rope is specially braided from galvanized wire and used in overhead power transmission line stringing operations.

Brand: QIAN YUAN

Payment Type: T/T, L/C

Incoterm: FCA, FOB, CFR, CIF

MOQ: 1KM

Productivity: 50KM per month

Transportation: Ocean, Land, Air

Packaging: Standard Steel Reel

Place of Origin: CHINA

Certificate: By China High Voltage Institute.

Delivery Time: 5-10 days

Product Status: In stock for 20KM each type, max 3-4 weeks required if for more mass production.

View More Anti Twist Wire Rope From QYPOWERLINE

Pulling Cable Pilot Wire Rope

Galvanized Steel Pilot Wire Rope, is also known as braided anti-twisting steel wire rope, also known as anti-torsion wire rope. Its manufacturing principle is regularly woven with a group of left twist and a group of right twist single-strand circular steel rope (crossed spiral track). Among them, the number of left twist strands and right twist strands is equal and braided symmetrically. The two groups of spiral moments are balanced due to the opposite direction so that the anti-twist wire rope does not have rotation characteristics when stressed.

It completely overcomes the rotation characteristics, achieves no rotation, does not tie ropes in use, has good flexibility and large tension force, and is widely used as traction ropes in electric power transmission line projects. or it is widely used in hoisting, transportation, rigging, horizontal traction, and other operations, and the market is very broad for its wide application.

According to its cross-section, it can be divided into squares and hexagons, and according to the number of strands, it can be divided into eight strands, twelve strands, and eighteen strands.

Remarks: All kinds of anti twist wire rope can be made according to the customers’ requirements.

Technical Parameters:

Product No. | Model | Strand Structure | Nominal Dia.(mm) | Strand Dia.(mm) | Nominal Tensile Strength (Mpa) | Strand Breaking Force(KN) | Steel Rope Referenced Weight(kg/km) |

1001 | GS9-12*19W | 6 Forms 12 Strands | 9 | 2 | 1960 | 67 | 299 |

1002 | GS11-12*19W | 11 | 2.5 | 1960 | 87 | 434 | |

1003 | GS13-12*19W | 13 | 3 | 1960 | 125 | 632 | |

1004 | GS15-12*19W | 15 | 3.5 | 2000 | 168 | 862 | |

1005 | GS18-12*19W | 18 | 4 | 1960 | 205 | 1098 | |

1006 | GS20-12*25Fi | 20 | 4.2-4.5 | 1960 | 255 | 1292 | |

1007 | GS20-12*29Fi | 20 | 4.2-4.5 | 1960 | 262 | 1302 | |

1008 | GS22-12*25Fi | 22 | 4.8 | 1960 | 309 | 1558 | |

1009 | GS22-12*29Fi | 22 | 4.8 | 1960 | 345 | 1784 | |

10010 | GS24-12*25Fi | 24 | 5.0-5.2 | 1960 | 355 | 1820 | |

10011 | GS24-12*29Fi | 24 | 5.0-5.2 | 1960 | 370 | 1995 | |

10012 | GS25-12*25Fi | 25 | 5.2-5.5 | 1960 | 389 | 2158 | |

10013 | GS25-12*29Fi | 25 | 5.2-5.5 | 2160 | 425 | 2247 | |

10014 | GS26-12*25Fi | 26 | 5.5-5.6 | 1960 | 420 | 2278 | |

10015 | GS26-12*29Fi | 26 | 5.5-5.6 | 2160 | 430 | 2298 | |

10016 | GS28-12*25Fi | 28 | 6 | 1960 | 440 | 2308 | |

10017 | GS28-12*29Fi | 28 | 6 | 2160 | 490 | 2568 | |

10018 | GS30-12*25Fi | 30 | 6.5 | 1960 | 485 | 2718 | |

10019 | GS30-12*29Fi | 30 | 6.5 | 2160 | 550 | 3098 |

Product No. | Model | Strand Structure | Nominal Dia.(mm) | Strand Dia.(mm) | Nominal Tensile Strength (Mpa) | Strand Breaking Force(KN) | Steel Rope Referenced Weight(kg/km) |

10020 | GS7-8*19W | 4 Forms 8 Strands | 7 | 2 | 1960 | 42 | 193 |

10021 | GS9-8*19W | 9 | 2.5 | 1960 | 57 | 289 | |

10022 | GS11-8*19W | 11 | 3 | 1960 | 78 | 398 | |

10023 | GS13-8*19W | 13 | 3.5 | 1960 | 110 | 580 | |

10024 | GS15-8*19W | 15 | 4 | 1960 | 125 | 690 | |

10025 | GS18-8*25Fi | 18 | 4.8-5.0 | 1960 | 206 | 1035 | |

10026 | GS18-8*29Fi | 18 | 4.8-5.0 | 2060 | 220 | 1078 | |

10027 | GS20-8*25Fi | 20 | 5.2-5.5 | 2060 | 245 | 1200 | |

10028 | GS22-8*25Fi | 22 | 6 | 1960 | 304 | 1535 | |

10029 | GS9-12*19W | 4 Forms 12 Strands | 9 | 2 | 1960 | 67 | 295 |

10030 | GS11-12*19W | 11 | 2.5 | 1960 | 83 | 430 | |

10031 | GS13-12*19W | 13 | 3 | 1960 | 125 | 630 | |

10032 | GS15-12*19W | 15 | 3.5 | 1960 | 170 | 865 | |

10033 | GS18-12*19W | 18 | 4 | 1960 | 198 | 1098 | |

10034 | GS20-12*25Fi | 20 | 4.2-4.5 | 1960 | 253 | 1285 | |

10035 | GS20-12*29Fi | 20 | 4.2-4.5 | 1960 | 262 | 1302 | |

10036 | GS22-12*25Fi | 22 | 4.8 | 1960 | 310 | 1555 | |

10037 | GS22-12*29Fi | 22 | 4.8-5.2 | 1960 | 318 | 1785 | |

10038 | GS24-12*25Fi | 24 | 5.0-5.2 | 1960 | 370 | 1850 | |

10039 | GS24-12*29Fi | 24 | 5.0-5.2 | 1960 | 370 | 2002 | |

10040 | GS25-12*25Fi | 25 | 5.2-5.5 | 2160 | 425 | 2161 | |

10041 | GS25-12*29Fi | 25 | 5.2-5.5 | 2160 | 430 | 2252 | |

10042 | GS26-12*25Fi | 26 | 5.5-5.6 | 1960 | 398 | 2298 | |

10043 | GS26-12*29Fi | 26 | 5.5-5.6 | 2160 | 420 | 2303 | |

10044 | GS28-12*25Fi | 28 | 6 | 1960 | 458 | 2312 | |

10045 | GS28-12*29Fi | 28 | 6 | 2160 | 486 | 2571 | |

10046 | GS30-12*25Fi | 30 | 6.5 | 1960 | 525 | 2722 | |

10047 | GS30-12*29Fi | 30 | 6.5 | 2160 | 535 | 3102 |