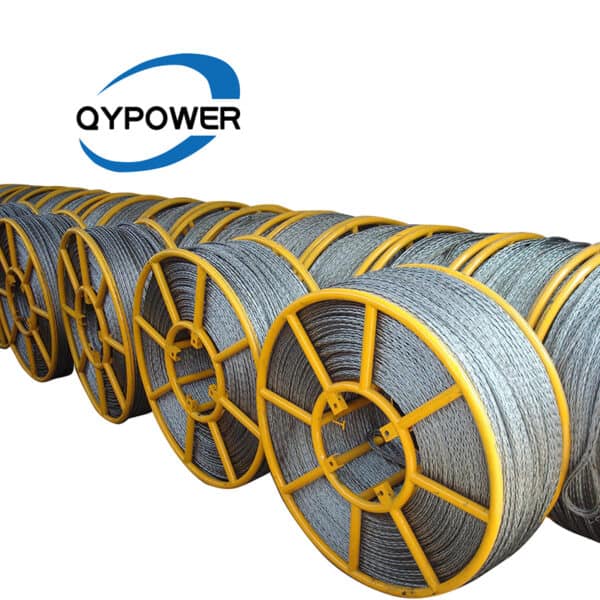

Anti Twisting Steel Wire Rope

Scope of application: Galvanized Anti Twisting Steel Wire Rope is specially used for pulling conductors in electric power line transmission project.

Brand: QIANYUAN

Payment Type: T/T, L/C

Incoterm: FCA, FOB, CFR, CIF

MOQ: 1KM

Productivity: 50KM per month

Transportation: Ocean, Land, Air

Packaging: Standard Steel Reel

Place of Origin: CHINA

Certificate: By China High Voltage Institute.

Delivery Time: 5-10 days

Product Status: In stock for 20KM each type, max 3-4 weeks required if for more mass production.

View More Anti Twist Wire Rope From QYPOWERLINE

Anti Twisting Steel Wire Rope

The special Anti-Twisting Steel Wire Rope is widely used in power line stringing operations, for pulling conductors, OPGW cable, ADSS, 500kv traction rope, etc. It is specially braided from galvanized steel wire and widely used as pilot rope in overhead power transmission line stringing operations.

1. The rotation angle is zero, and the combined rotation torque is also zero while it is bearing tension at a free state. It is suitable to be used in various fields which require wire rope with no rotation.

2. The wire rope has fine flexibility with a long using life. There is no twist and no tangling up when the tension is released. You can change the length and repair local damage by grafting, which will not reduce the flexibility.

3. Hexagon anti-twist rope is more suitable for the hydraulic puller, tensioner, engine powered winch, hoisting etc .

Features: Square or hexagon is braided with four-strand, six-strand, or nine-strand twisting with each other leftwards or rightwards. It is relative to the section. The twisting force on the section can be released each other whether it receives a force or not. The moment of twisting is naught for the wire rope. The special pilot wire is widely used in power line stringing operations, for pulling conductors, OPGW cable, ADSS, 500kv traction rope, etc.

Remarks: All kinds of Anti Twisting Steel Wire Rope can be made according to the customers` requirements.

Technical Parameters:

Product No. | Model | Strand Structure | Nominal Dia.(mm) | Strand Dia.(mm) | Nominal Tensile Strength (Mpa) | Strand Breaking Force(KN) | Steel Rope Referenced Weight(kg/km) |

1001 | GS9-12*19W | 6 Forms 12 Strands | 9 | 2 | 1960 | 67 | 299 |

1002 | GS11-12*19W | 11 | 2.5 | 1960 | 87 | 434 | |

1003 | GS13-12*19W | 13 | 3 | 1960 | 125 | 632 | |

1004 | GS15-12*19W | 15 | 3.5 | 2000 | 168 | 862 | |

1005 | GS18-12*19W | 18 | 4 | 1960 | 205 | 1098 | |

1006 | GS20-12*25Fi | 20 | 4.2-4.5 | 1960 | 255 | 1292 | |

1007 | GS20-12*29Fi | 20 | 4.2-4.5 | 1960 | 262 | 1302 | |

1008 | GS22-12*25Fi | 22 | 4.8 | 1960 | 309 | 1558 | |

1009 | GS22-12*29Fi | 22 | 4.8 | 1960 | 345 | 1784 | |

10010 | GS24-12*25Fi | 24 | 5.0-5.2 | 1960 | 355 | 1820 | |

10011 | GS24-12*29Fi | 24 | 5.0-5.2 | 1960 | 370 | 1995 | |

10012 | GS25-12*25Fi | 25 | 5.2-5.5 | 1960 | 389 | 2158 | |

10013 | GS25-12*29Fi | 25 | 5.2-5.5 | 2160 | 425 | 2247 | |

10014 | GS26-12*25Fi | 26 | 5.5-5.6 | 1960 | 420 | 2278 | |

10015 | GS26-12*29Fi | 26 | 5.5-5.6 | 2160 | 430 | 2298 | |

10016 | GS28-12*25Fi | 28 | 6 | 1960 | 440 | 2308 | |

10017 | GS28-12*29Fi | 28 | 6 | 2160 | 490 | 2568 | |

10018 | GS30-12*25Fi | 30 | 6.5 | 1960 | 485 | 2718 | |

10019 | GS30-12*29Fi | 30 | 6.5 | 2160 | 550 | 3098 |

Product No. | Model | Strand Structure | Nominal Dia.(mm) | Strand Dia.(mm) | Nominal Tensile Strength (Mpa) | Strand Breaking Force(KN) | Steel Rope Referenced Weight(kg/km) |

10020 | GS7-8*19W | 4 Forms 8 Strands | 7 | 2 | 1960 | 42 | 193 |

10021 | GS9-8*19W | 9 | 2.5 | 1960 | 57 | 289 | |

10022 | GS11-8*19W | 11 | 3 | 1960 | 78 | 398 | |

10023 | GS13-8*19W | 13 | 3.5 | 1960 | 110 | 580 | |

10024 | GS15-8*19W | 15 | 4 | 1960 | 125 | 690 | |

10025 | GS18-8*25Fi | 18 | 4.8-5.0 | 1960 | 206 | 1035 | |

10026 | GS18-8*29Fi | 18 | 4.8-5.0 | 2060 | 220 | 1078 | |

10027 | GS20-8*25Fi | 20 | 5.2-5.5 | 2060 | 245 | 1200 | |

10028 | GS22-8*25Fi | 22 | 6 | 1960 | 304 | 1535 | |

10029 | GS9-12*19W | 4 Forms 12 Strands | 9 | 2 | 1960 | 67 | 295 |

10030 | GS11-12*19W | 11 | 2.5 | 1960 | 83 | 430 | |

10031 | GS13-12*19W | 13 | 3 | 1960 | 125 | 630 | |

10032 | GS15-12*19W | 15 | 3.5 | 1960 | 170 | 865 | |

10033 | GS18-12*19W | 18 | 4 | 1960 | 198 | 1098 | |

10034 | GS20-12*25Fi | 20 | 4.2-4.5 | 1960 | 253 | 1285 | |

10035 | GS20-12*29Fi | 20 | 4.2-4.5 | 1960 | 262 | 1302 | |

10036 | GS22-12*25Fi | 22 | 4.8 | 1960 | 310 | 1555 | |

10037 | GS22-12*29Fi | 22 | 4.8-5.2 | 1960 | 318 | 1785 | |

10038 | GS24-12*25Fi | 24 | 5.0-5.2 | 1960 | 370 | 1850 | |

10039 | GS24-12*29Fi | 24 | 5.0-5.2 | 1960 | 370 | 2002 | |

10040 | GS25-12*25Fi | 25 | 5.2-5.5 | 2160 | 425 | 2161 | |

10041 | GS25-12*29Fi | 25 | 5.2-5.5 | 2160 | 430 | 2252 | |

10042 | GS26-12*25Fi | 26 | 5.5-5.6 | 1960 | 398 | 2298 | |

10043 | GS26-12*29Fi | 26 | 5.5-5.6 | 2160 | 420 | 2303 | |

10044 | GS28-12*25Fi | 28 | 6 | 1960 | 458 | 2312 | |

10045 | GS28-12*29Fi | 28 | 6 | 2160 | 486 | 2571 | |

10046 | GS30-12*25Fi | 30 | 6.5 | 1960 | 525 | 2722 | |

10047 | GS30-12*29Fi | 30 | 6.5 | 2160 | 535 | 3102 |