Fast and Efficient: The Benefits of Fiber Optic Laying Machines in Modern Communication

Fiber optic laying machines are specialized equipment used for the installation of fiber optic cables….

Fiber optic laying machines are specialized equipment used for the installation of fiber optic cables. These machines have revolutionized the way we connect with one another, allowing for faster and more efficient communication across the globe. The importance of fiber optic cables in modern communication cannot be overstated, making the need for efficient and speedy laying of these cables all the more critical.

II. Types of Fiber Optic Laying Machines

There are several types of fiber optic laying machines, each designed for specific terrain and installation requirements. These include plowing machines, trenching machines, horizontal directional drilling machines, and blowing machines.

A. Plowing Machines

Plowing machines are commonly used for installing fiber optic cables in soft soil or grassy terrain. These machines use a specialized plow that cuts a narrow trench into the ground, laying the fiber optic cable in the trench as it goes. Plowing machines are fast, efficient, and can cover long distances quickly.

B. Trenching Machines

Trenching machines are used for installing fiber optic cables in hard soil or rocky terrain. These machines use a chain trencher to cut a narrow trench into the ground, laying the fiber optic cable in the trench as it goes. Trenching machines are slower than plowing machines but are more precise and can be used in a wider range of terrains.

C. Horizontal Directional Drilling Machines

Horizontal directional drilling machines are used for installing fiber optic cables under roads, rivers, and other obstacles. These machines use a directional drill to bore a hole underground, laying the fiber optic cable in the hole as it goes. Horizontal directional drilling machines are precise, but slower than plowing or trenching machines.

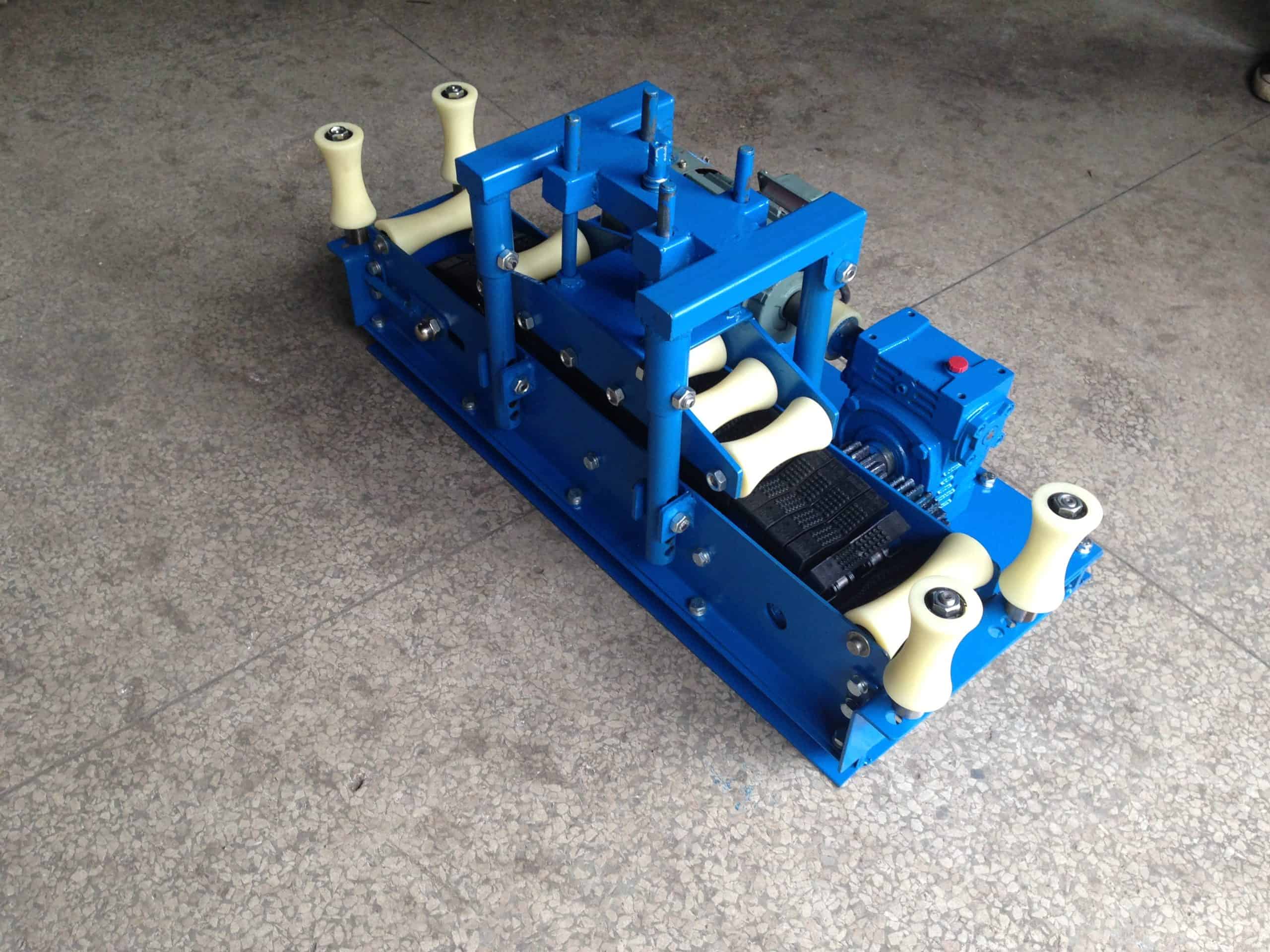

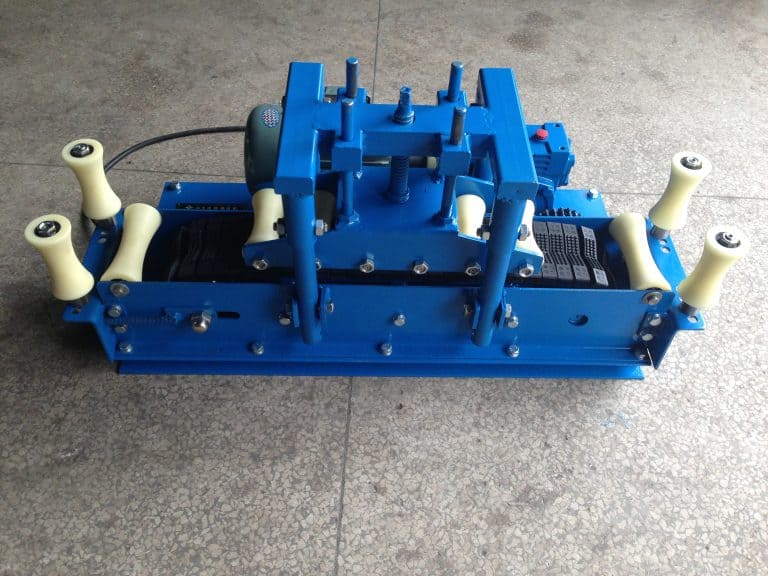

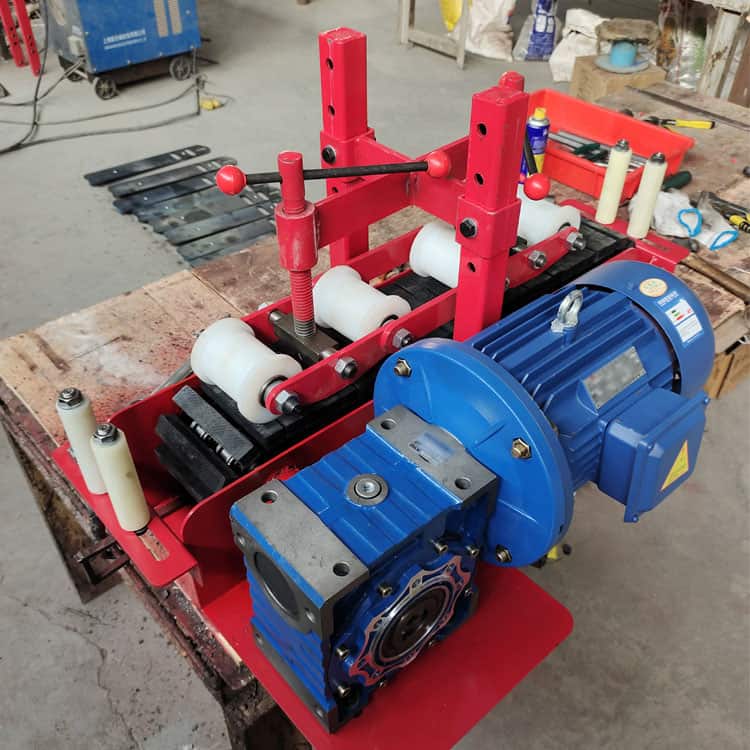

D. Blowing Machines

Blowing machines are used for installing fiber optic cables in pre-existing ducts or pipes. These machines use compressed air to blow the fiber optic cable through the duct, minimizing any potential damage to the surrounding environment.

III. How Fiber Optic Laying Machines Work

Each type of fiber optic laying machine works differently, depending on the terrain and installation requirements.

A. Plowing Machines

Plowing machines use a specialized plow that cuts a narrow trench into the ground, laying the fiber optic cable in the trench as it goes. The plow can be adjusted to the required depth, and the fiber optic cable is fed through the plow from a spool on the machine.

B. Trenching Machines

Trenching machines use a chain trencher to cut a narrow trench into the ground, laying the fiber optic cable in the trench as it goes. The trencher can be adjusted to the required depth, and the fiber optic cable is fed through the trencher from a spool on the machine.

C. Horizontal Directional Drilling Machines

Horizontal directional drilling machines use a directional drill to bore a hole underground, laying the fiber optic cable in the hole as it goes. The drill can be controlled remotely, allowing for precise placement of the fiber optic cable.

D. Blowing Machines

Blowing machines use compressed air to blow the fiber optic cable through pre-existing ducts or pipes. The fiber optic cable is fed into the duct or pipe from a spool on the machine, and the compressed air pushes the cable through the duct or pipe to its destination.

IV. Advantages of Using Fiber Optic Laying Machines

The use of fiber optic laying machines offers several advantages over traditional methods of laying fiber optic cables.

A. Speed and Efficiency

Fiber optic laying machines are faster and more efficient than traditional methods of laying fiber optic cables. They can cover long distances quickly and accurately, reducing installation time and costs.

B. Cost-effectiveness

Fiber optic laying machines are cost-effective, as they require fewer workers and can cover more ground in less time. This translates into lower installation costs for companies and organizations.

C. Minimal Damage to Surrounding Environment

Fiber optic laying machines cause minimal damage to the surrounding environment, as they require less digging and excavation than traditional methods of laying fiber optic cables. This reduces the disruption to the surrounding area and minimizes the impact on the environment.

D. Easy Maintenance

Fiber optic laying machines are easy to maintain, as they are designed for durability and require minimal upkeep. This reduces maintenance costs for companies and organizations.

V. Limitations of Fiber Optic Laying Machines

Despite their advantages, fiber optic laying machines have some limitations that must be considered.

A. High Initial Investment

Fiber optic laying machines require a significant initial investment, which may be prohibitive for smaller companies and organizations.

B. Dependence on Favorable Weather Conditions

Fiber optic laying machines are dependent on favorable weather conditions for installation, and adverse weather conditions can cause delays and increase installation costs.

C. Need for Skilled Operators

Fiber optic laying machines require skilled operators to operate them effectively, which may require additional training and recruitment costs.

D. Limited Applicability in Certain Terrains

Fiber optic laying machines may have limited applicability in certain terrains, such as rocky or mountainous terrain, where traditional methods of laying fiber optic cables may be more suitable.

VI. Conclusion

Fiber optic laying machines have revolutionized the way we connect with one another, allowing for faster and more efficient communication across the globe. While they have some limitations, their advantages make them a valuable investment for companies and organizations seeking to expand their communication networks. As technology continues to advance, the future of fiber optic laying machines in modern communication looks promising.

ofc cable blowing machine, miniflow rapid blowing machine, fiber blowing machine price, fiber pulling machine, blowing machine fiber optic, ofc cable blowing machine price, fiber optic cable pulling machine, cable pusher, fiber cable pulling machine, fiber optic laying machine.