Essential fiber optic cable installation equipment for Cable Installation

I. Introduction of fiber optic cable installation equipment Fiber optic cable installation is a complex…

I. Introduction of fiber optic cable installation equipment

Fiber optic cable installation is a complex process that requires a range of specialized fiber optic cable installation equipment. Whether you’re installing fiber optic cables for a data center, a telecommunications network, or a residential broadband connection, using the right equipment is essential to ensure a successful installation.

II. Fiber Optic Cable Preparation Equipment

Before you can install a fiber optic cable, you need to prepare it for splicing and termination using fiber optic cable installation equipment. This involves removing the outer jacket, separating the fibers, and cutting them to the correct length. The following equipment is essential for fiber optic cable preparation:

A. Fiber optic cable cutter – A cable cutter is used to cut the outer jacket of the fiber optic cable without damaging the inner fibers.

B. Cable jacket stripper – A jacket stripper removes the outer jacket from the fiber optic cable, exposing the individual fibers.

C. Kevlar scissors – Kevlar scissors are used to cut the Kevlar strands that reinforce the fiber optic cable. This allows you to access the individual fibers and splice them together.

III. Fiber Optic Cable Splicing Equipment

Splicing is the process of joining two fiber optic cables together using fiber optic cable installation equipment. There are two main types of splicing: fusion splicing and mechanical splicing. The following equipment is essential for fiber optic cable splicing:

A. Fusion splicer – A fusion splicer uses an electric arc to melt the ends of two fiber optic cables together, creating a permanent bond. This type of splicing is ideal for high-bandwidth applications and can be used for single-mode and multimode fibers.

B. Mechanical splicer – A mechanical splicer uses a precision clamp to align the ends of two fiber optic cables and hold them together. This type of splicing is faster and less expensive than fusion splicing, but it’s not as reliable for high-bandwidth applications.

C. Cleaver – A cleaver is used to cut the ends of the fiber optic cables cleanly and evenly before splicing.

IV. Fiber Optic Cable Testing Equipment

After you’ve installed and spliced the fiber optic cables, you need to test them to ensure they’re working properly using fiber optic cable installation equipment. The following equipment is essential for fiber optic cable testing:

A. Optical time-domain reflectometer (OTDR) – An OTDR sends a pulse of light down the fiber optic cable and measures the reflections to determine the length and quality of the cable.

B. Optical power meter (OPM) – An OPM measures the amount of light that’s transmitted through the fiber optic cable to ensure it meets the required specifications.

C. Visual fault locator (VFL) – A VFL uses a visible laser to detect faults in the fiber optic cable, such as breaks or bends.

V. Conclusion

Fiber optic cable installation requires a range of specialized equipment for preparation, splicing, and testing. By using the right equipment, you can ensure a successful installation and reliable performance for your network. Make sure you have all the necessary fiber optic cable installation equipment before you begin your fiber optic cable installation

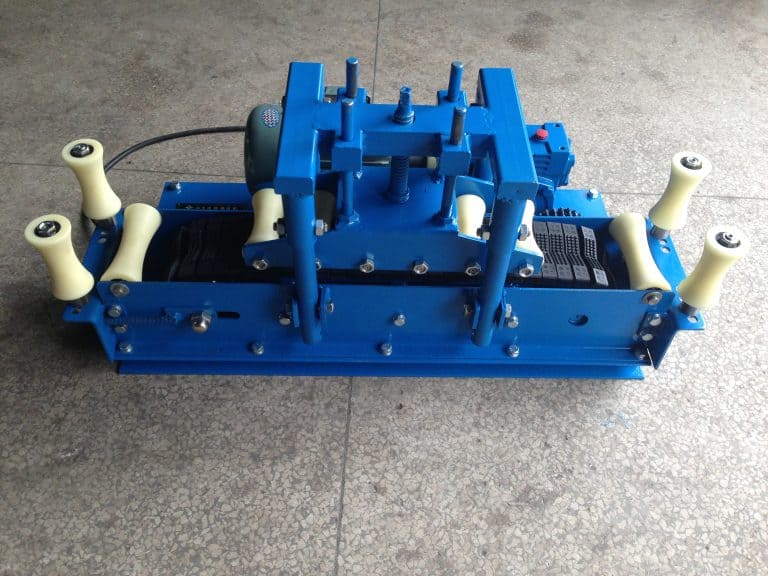

cbs blowing machine, air blown fiber machine, gmp fiber blower, cable blowing machine, cable pusher for sale, ofc blowing machine price, fiber optic blowing machine price, fiber optic cable blower, fibre blowing machine for sale, ofc cable pulling machine price.