What is the benefit to use engine driven hydraulic power unit?

If your hydraulic system needs a lot of power, there is no better option than…

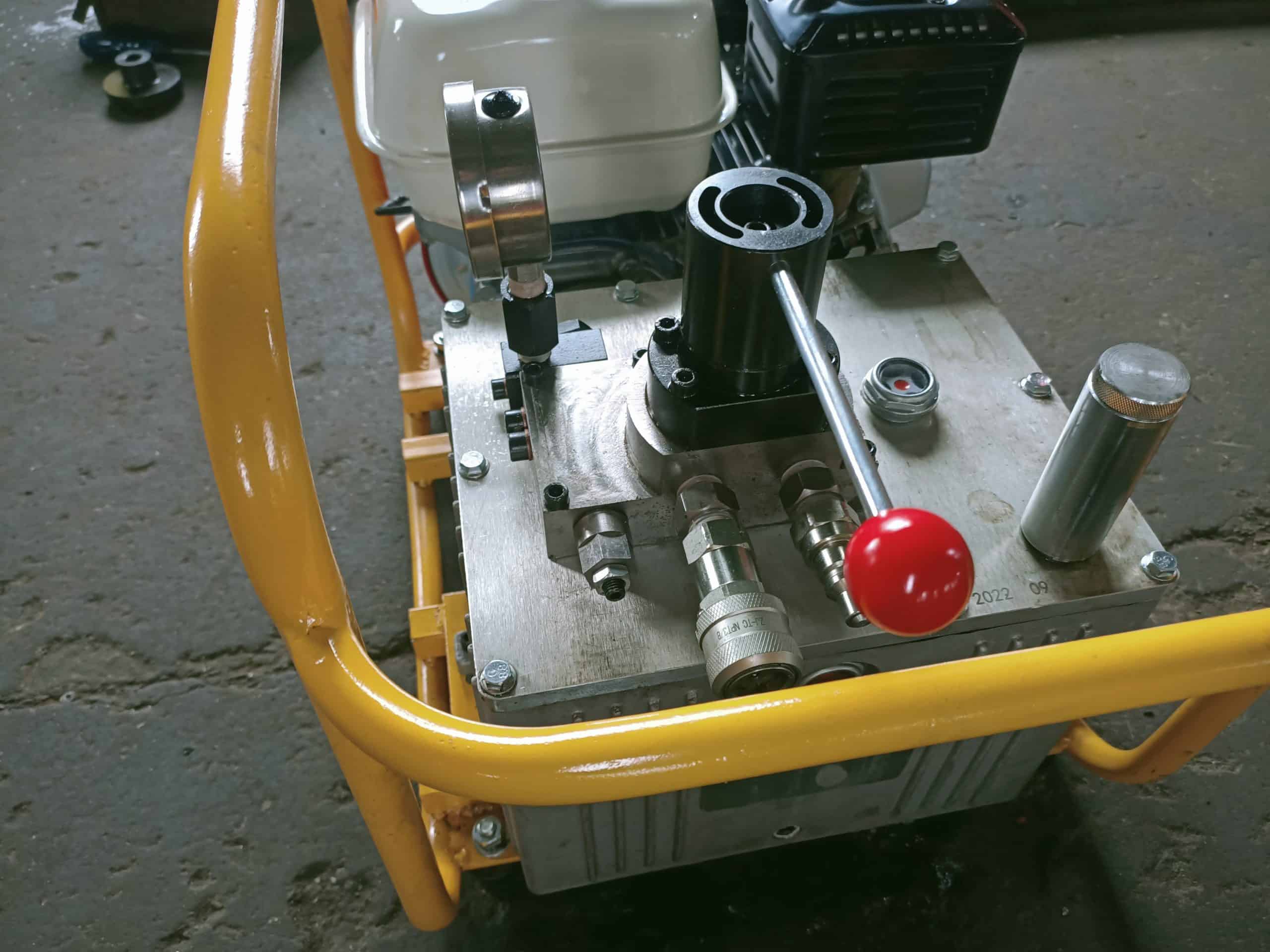

If your hydraulic system needs a lot of power, there is no better option than the selection of petrol engine driven hydraulic power unit. We have available at Flowfit. To ensure a durable and effective service, we have rigorously evaluated every product we offer. To satisfy your hydraulic standards, our models are offered in a variety of specifications. In a hydraulic system, fluid is confined to transport energy from one source to another, producing rotational motion, linear motion, or force as a result. For this fluid transfer, the power is provided by the power unit or pack. engine engine-driven power units, as opposed to conventional pumps, transport fluid using multi-stage pressurisation networks and frequently, include temperature control components. A hydraulic power unit’s mechanical attributes and specifications determine the kinds of tasks it can be used for.

Why Use an Engine Driven Hydraulic Power Pack?

For their work as industry leaders in the development and production of hydraulic power packs, Hydraproducts is well-known on a global scale. Our goods are used for a variety of purposes across many different sectors. The engine driven hydraulic power unit and its integration with hydraulic systems in a number of industries, including manufacturing, renewable energy, and construction, are among our areas of competence.

Operating Process of Hydraulic Power Units

The gear pump removes hydraulic fluid from the tank and puts it into an accumulator when an engine-driven hydraulic power unit starts to operate. A charging valve switches the pumping action to start fluid circulation when the pressure inside the accumulator reaches a specific level. This process continues until that point. The pump then releases fluid at low pressure through a charging valve and back into the tank as a result. A unique one-way valve prevents fluid from escaping the accumulator, but if the pressure significantly drops, the charging valve reactivates, refilling the accumulator with fluid. The flow of oil traveling to the actuators is controlled farther along the line by a reduced-pressure valve.

Other accumulators can be linked to an accumulator that has a fast-stroking device so that it can charge pressure as well. To reduce rising temperatures, an automatic thermostat or fan is frequently added. The motor pump can be stopped by a temperature switch if the fluid in the system starts to overheat. If the fluid level in the tank is too low, the temperature switch can also help to fill the tank. A flow switch can alternate the motor pumps in the engine-driven hydraulic power unit if it has multiple motor pumps in the event of a low fluid supply. When accumulator pressure drops too low, increasing the possibility of a power unit failure, pressure switches can be employed to manage the pressure, and a monitoring system can notify operators.

double acting hydraulic power pack, petrol powered hydraulic pump, used hydraulic power unit for sale, engine powered hydraulic pump, motor driven hydraulic pump, honda gx160 hydraulic power pack, engine driven hydraulic power pack, engine driven pump hydraulic system, diesel powered hydraulic power unit, gas power hydraulic pump.